Went into this little project with a degree of apprehension... running the fuel feed hard line from the rear of the car to the front.

I experimented with a length of tube out of the VZ. OK, but a bit tough to bend and the real concern was routing over the rear axle, as well as bending up into the engine bay.

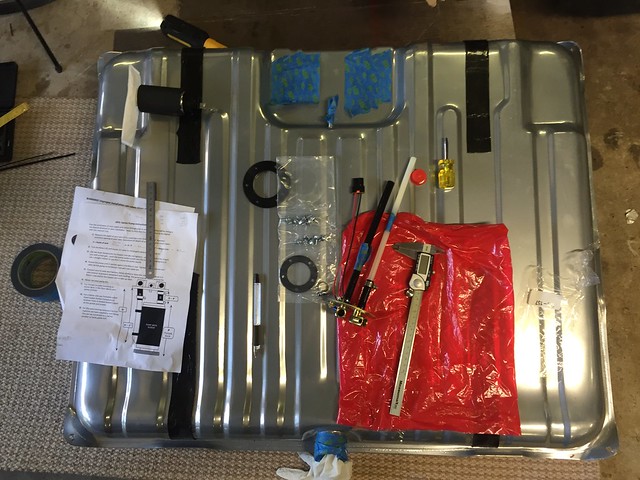

But first, some new shiny bits...

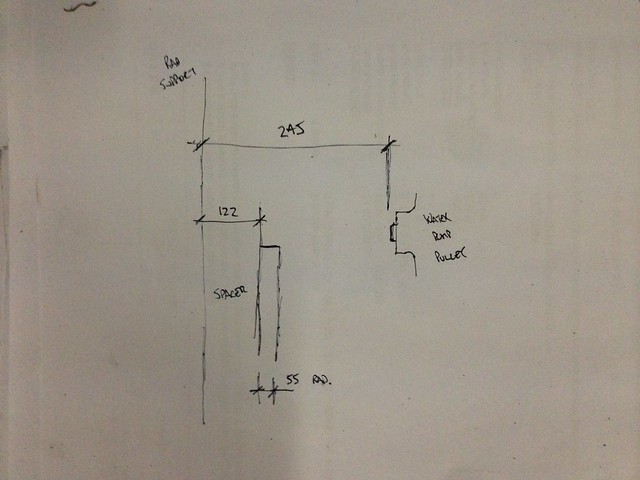

The black hose is for the power steering high pressure line from the pump to the steering box (another story). For today, we are concentrating on the coil of new 3/8" tubing and Speedflow hardline adaptors.

So the plan is...

GM female 3/8" QD on the filter output...

-> Speedflow GM 3/8" EFI adaptor to male AN-6 (716-06-06-BLK)

-> Speedflow male AN-6 to female AN-6 3/8" hardline adaptor (619-06-06-BLK)

-> Speedflow 3/8" hardline

-> Speedflow female AN-6 3/8" hardline adaptor (619-06-06-BLK)

-> Speedflow GM 3/8" EFI adaptor to male AN-6 (716-06-06-BLK)

-> fuel hose from the VZ.

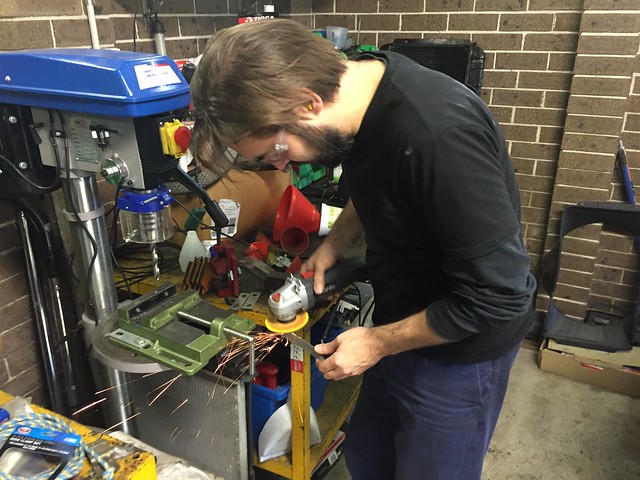

Time to get JtC on the case...

Without seeing the job, there were no concerns.... easy!

Once on a creeper and under the car, the bend over the axle and the bends into the engine bay weren't looking so easy.

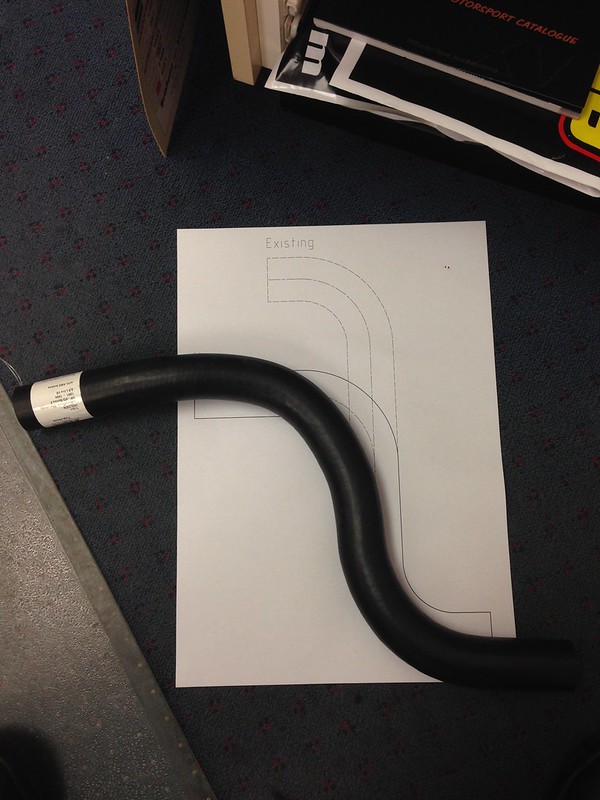

The decision was made to butcher the VZ fuel hose and make our own EFI rubber hose with the GM quick disconnect fittings to run from the engine, down to the chassis rail. Then it would be hard line to the axle where we would swap back to flexible hose for the axle bend.

A plan!

For a bit of laugh, JtC thought he would have a quick try bending the Speedflow hard line up and over the axle.

We shouldn't have been concerned, the new hard tubing was a lot more flexible and easier to work with than the original Holden lines.

Next minute... hard line routed over the axle, over the trans cross member, even clipped into the original Chev retaining clips...

We were able to un-spool the coil of tubing up and into the engine bay, retaining the tubing with P-clips...

A thing of beauty!

Because we butchered the VZ fuel hose to the engine, we had to recreate it with EFI rubber hose. Here it is waiting for two more EFI hose clamps (what a time to run out)...

BIG thanks to JtC for weaving his car whispering magic once again!

J