To fix the LS into place in the Chev engine bay, we used standard Chev SBC engine mounts with adaptor plates to pick-up the bolt holes on the LS block.

It seems the standard rubber bonded to steel mounts don't much like LS 6.0L torque...

This is the second mount to snap on the tension side since the conversion, so time to rethink the whole engine mount solution methinks.

Enter Tuff Mounts...

New vs. Old...

Like the original adaptor plate/standard mount/standard pedestal solution, she no fit...

Like before, time to break-out some plywood to use as templating material and mock-up some new pedestals...

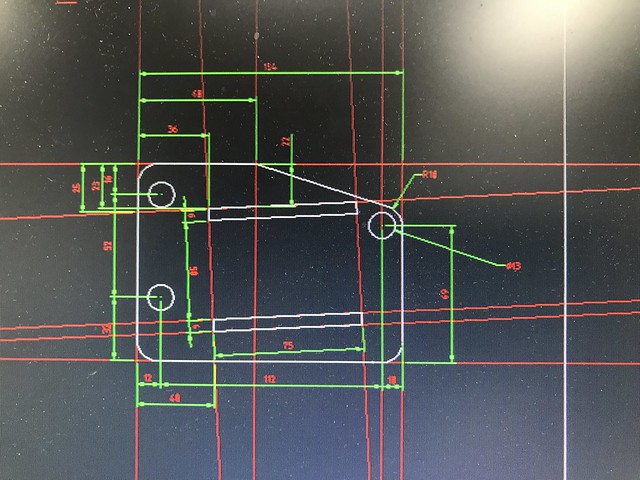

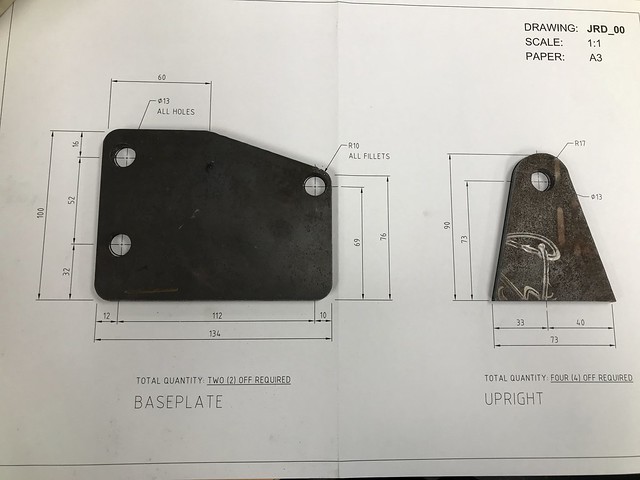

Things may have gotten a little out of hand. When you break out the CAD for a pair of simple engine mounts, it is a good sign I maaay have over-thought this little project...