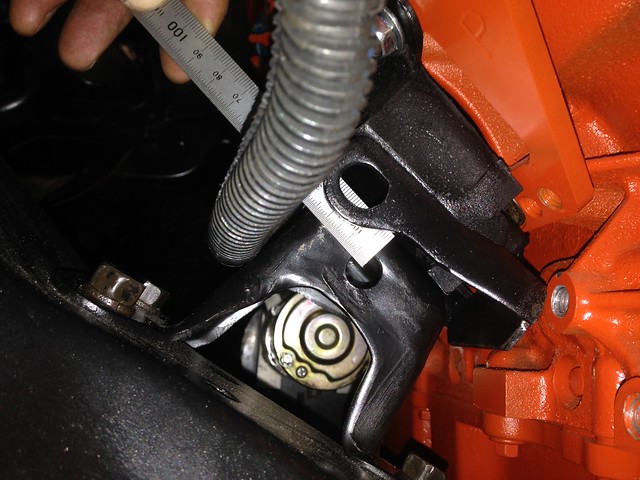

We are old hands at the process and soon had the engine bolted up on one side... but no joy on the other with the mount holes out of alignment to the pedestal holes by 10 mm.

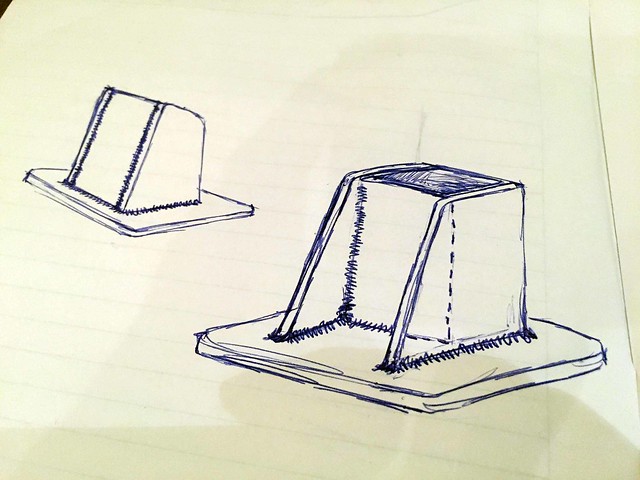

Soul-searching insued trying to figure out a) what went wrong and - more to the point - b) how to fix it.

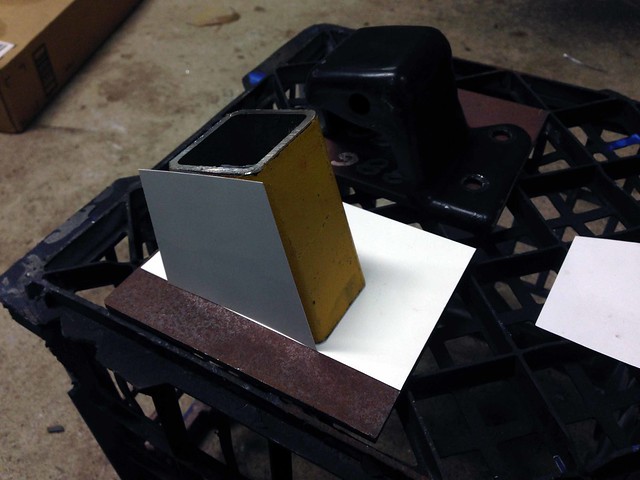

The original Chev engine mounts had long slots in the mounting holes, so the decision was to lift the engine clear of the pedestals just enough to swap the mounts out.

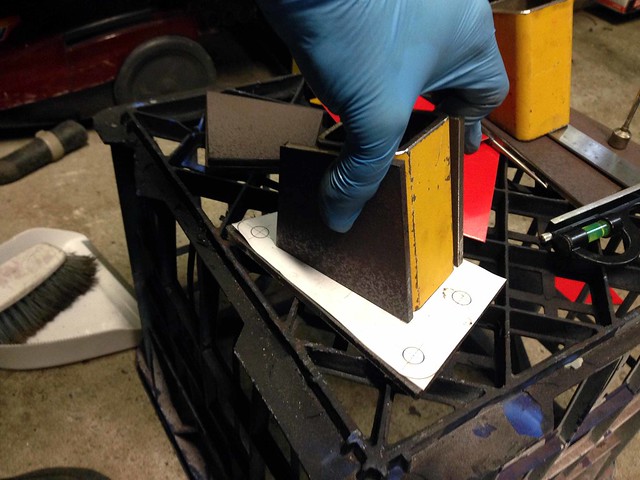

Before we did, JtC opened up the slots a bit more to give us every opportunity of getting this sucker home to its final resting spot, while I ground down the pedestals (in situ) to ensure the mounts could sit low enough to get the holes to line-up.

Drill/file/grind/paint and - with the new modified arrangement - the 6.0L dropped in like Chev designed it!

It turned out we didn't need to open the slots any further as the original mounts lined-up better than the reproduction items!

My dents in the trans tunnel were enough to clear the transmission servo.

Bolting the engine mounts in the next location forward on the adapter plates has set the engine back enough in the engine bay to ensure the exhaust now dumps behind the steering linkages.

This is a massive moment in the project and HUGE thanks to JtC for making the trip up and making the magic happen!

Next: gearbox crossmember.

J