Ever since converting to four wheel disc brakes, I have never been able to lock the rears and only just lock the fronts under hard braking. The Chev has always felt like it stopped well at low to medium demands, but hit the brakes hard and it would continue on further than I would have thought it would and certainly further than I like.

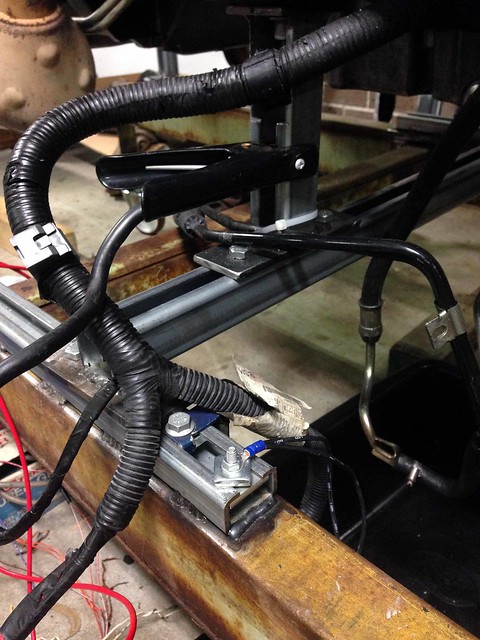

Time to try this:

"Right Stuff" Rear Disc Installation Support

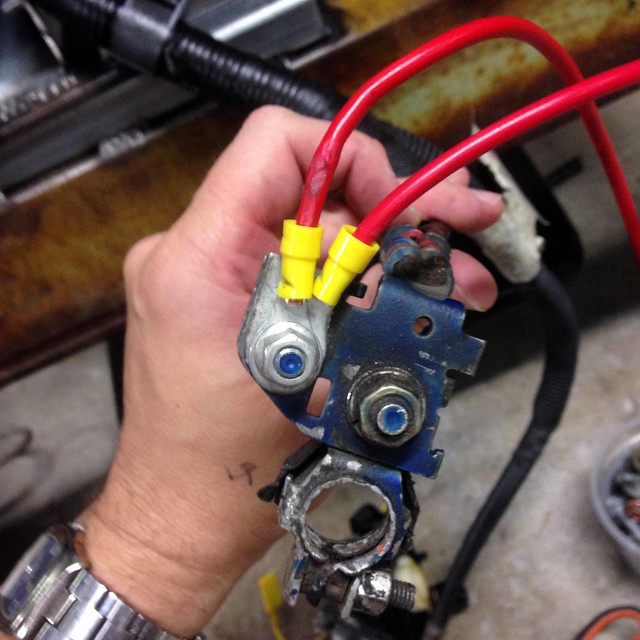

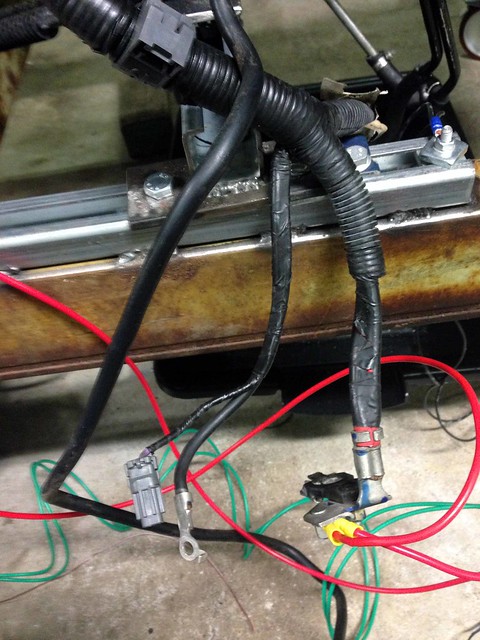

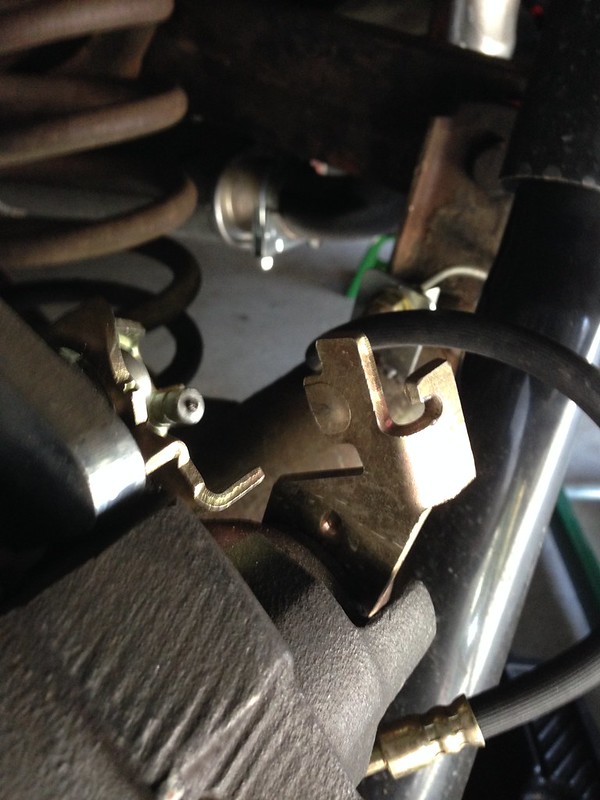

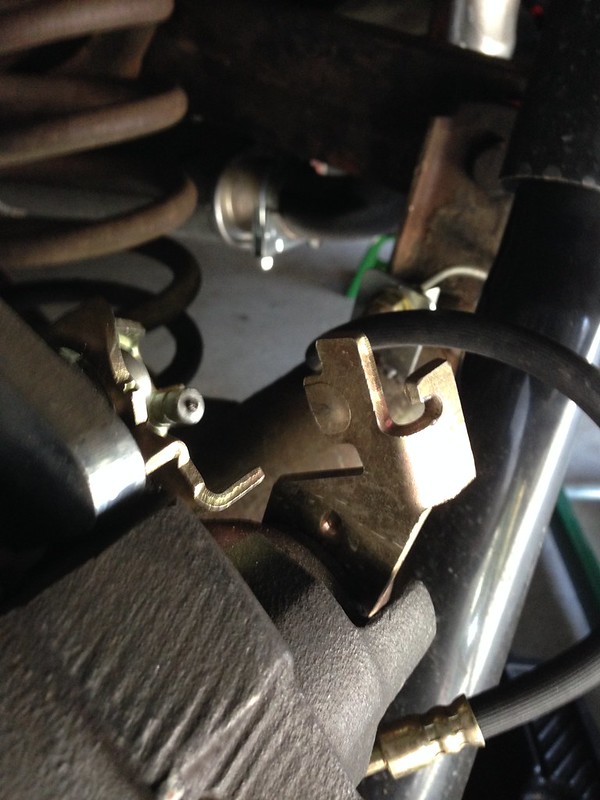

Up on stands, rear wheels off and pull the emergency brake actuation levers apart...

The rear discs didn't look like they had seen much use. Cross-hatching still visible....

Adjusting the emergency brake actuation... the right rear was pretty good, though the left rear could be wound out a turn and still have the lever placed against the end stop...

Back together and go for a test drive. Much better!

The pulls up quicker and the brake balance is good. I managed to lock the right rear under hard braking on the way to the servo with an empty petrol tank. Once filled, the extra weight at the back meant all four tyres would be on the verge of locking under heavy braking, with a front locking preferentially.

No brake fluid escaped during the adjustment, but the pedal does get harder after one pump so a bleed wouldn't go astray.

I'll also double-check that I have adjusted the emergency brake correctly, so there is no slack in the emergency brake system when released, but the caliper actuation lever is still on the end stop.

J